The short answer is YES! Standards enable everyday life. From paper sizes, think A4, to the building of a modern home that you may live in two examples of where standards are used and without them either of the aforementioned would not be possible.

Standards in print allow you to justify and account for the operational processes in manufacturing. Standards assist with your methodology in providing your customers with the expected printed product.

Utilising the colour quality standard ISO 12647-2 helps you to maintain customer satisfaction and loyalty and reduces the risk of costly reprints because of poor or out of tolerance colour. Print companies who keep up with the latest standards are building a reputation for quality through accreditation with a recognised standard.

Print buyers and brands are on the lookout for printers who have, and maintain, quality management systems with the necessary certifications.

You are probably aware that standards are constantly being updated, every 5 years or so. This can mean a minor revision to a complete re-write. With the rapid advancement of digital technology there are a number of changes underway with new ISO standards being developed.

New Standards in Print

The best known standard is ISO 12647-2, the offset colour. The latest release was in Dec 2013 and a review should be complete by next year. The values contained in this document are often used as a reference for other print processes and systems.

ISO 19301, 2 and 3 are emerging standards for colour quality management, colour conformity of a printing workflow and packaging printing colour reproduction.

Additional there will be reviews of ISO 15311-1 and 2, which covers measurement methods, reporting schema and print quality requirements. These can used for digital and traditional forms of printed materials.

There is also work under way to enable consistent and objective comparison of the colour gamut of different printing systems.

In a declining industry Packaging is one of the few areas to show slight, but steady increases in overall volume, year on year. A vital and large area of packaging is produced by the Flexo print process. Consistent brand colour is imperative here and with continuous improvements in Flexo print technology the use of spot colours within tonal reproduction is on the rise.

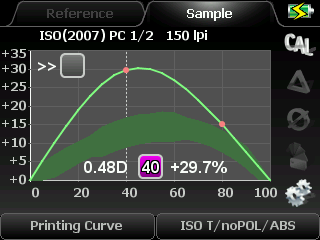

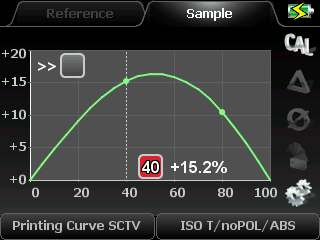

Checking for solid or 100% spot colours is well documented. The recently released ISO 20654 specifies the new method required for measuring the calculation of Spot Colour Tone Values (SCTV), which is much more accurate. This differs from the usually used Murray Davies formula used for process colours. This will most likely be used in the next revision of the ISO 12647-6 flexo standard. See the examples of 'normal' dot gain measurement Vs SCTV measurement on a 'RED' spot colour below.

Having a colour quality management system in place with good procedures, measurement and records requires a cross section of ,colour and QMS standards. Many print companies do have limited colour management (CM) policies, they believe in performing printer calibrations and their digital colour CM is looked after by their preferred digital equipment supplier, but this is not enough. It is only a small part of the equation. and in that situation you are not in control.

How to Keep up to Date?

To keep up date with new and changing standards, industry requirements and brand owner expectations is not an easy task. The internet of course has made communications and the transfer of knowledge and information much easier, but not always reliable.

There are usually local print industry groups and ISO Technical Committees (TC) who are more than willing to advise, help and listen to your opinion. If you feel that you input is warranted it is definitely worth your while to get in touch.

In Australia you might try Visual Connections https://www.visualconnections.org.au, or Printing Industries Assoc. of Aust. https://www.piaa.org.au/

You can of course stay in touch with me for all the latest in what's happening with colour standardisation, as I volunteer my time on the local TC130.

For more information about whats happening with colour standardisation and the benefits of using a Colour Spectrophotometer training and the TECHKON instrument range please contact us at info@colourgraphicservices.com.