When we are talking about printer profiling, we are actually talking about characterisation - which in itself is a recording of the way the device prints and produces colour on a substrate (just to clear things up). This characterisation data is saved into a print ICC profile.

And remember, the ICC profile alone does not do anything until it is used in an ICC transform with another device ICC profile. This is where the CMM (colour management module) comes into play - by looking at the characteristics of the two device ICC's through the CMM we can end up with a way transferring colour accurately from one device to another.

But, what is the best number of patches to use? 500 or 1500 or 3000 or more?

If the purpose of characterisation is to capture the colour behaviour of the device (in this case) then it makes sense that more patches should theoretically produce a better result.

Without completing many long winded laboratory tests experience has shown us that 3000-3500 characterisation patches works very well for inkjet, digital production and wide format devices. Now 3000 patches does not capture every colour the printer is capable of reproducing so there is some interpolation going when the profile is used.

To achieve perfect accuracy the characterisation should capture all the device input values, which for example for an RGB device would be 16.7 million.

We all probably know that no characterisation chart ever has millions of patches. For ICC profiles to be used effectively there a limit on the number of entries so that storage and speed of processing is not hindered.

For ease of understanding we will use the options available in the Myiro Tools software. One of the benefits of Myiro Tools is the core aim point that "Everything should be made as simple as possible, but not simpler."

This means we would like to achieve the best accuracy from the characterisation of the device with the minimum required data as can possibly be used.

Therefore, Myiro Tools offers fixed patch set with 420, 840 or 2520 patches - not quite 3000, but enough. Even though every colour is not captured with the patch sets above it still needs to be interpolated accurately and correctly.

As an example, for calibrating an old CRT (cathode ray tube) monitor we could simply measure white and then 100% red. Due to the very good linear characteristics of CRT's it was possible to accurately predict the 50% red colour.

For print devices it is a little different. Device calibration usually includes the linearisation process. From this we can then expect predictable linearity for 0-100% for each primary colour, CMYK. But when we start mixing combinations of CMYK on various media types this is where the result becomes less accurate and less predictable.

This is further compounded by the diversity in print processes and the types methodologies used in getting the ink to adhere to a substrate. Some processes will be more non-linear than others which then requires that the captured points should be optimised to capture the non-linearity.

This brings us to the point about using standard charts like the ISO IT8/7.4 or the ECI2002 or the TC1617. The whole purpose of these files is to validate and check colour of the output process. i.e. such as measuring the TC1617 to confirm G7 colour space to the desired CPRC or GRACoL target. These charts are not designed or purposed to be used to characterise print engines.

The Myiro Tools fixed patch sets (2520, 840 & 420) are subsets of each larger chart. The files have been optimised to achieve higher accuracy in gamut areas where print process behaviour can be uncertain and unstable.

Additionally, another benchmark for the patch values and number of patches to be used in a characterisation is the design and mathematics of the profiling software tool - with the Myiro Tools charts they are completely developed for the efficiency of the Myiro Tools software.

Still the question remains, 'How many patches or which chart to use?'

Myiro has the tools so you can check this and decide for yourself.

How to do it?

- Create a profile using the 420-patch file

- Print and measure a larger file such as the 840

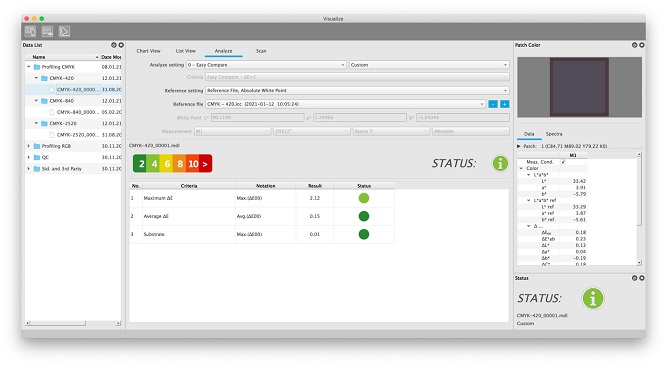

- Use the Myiro tools Analyze function and with "Easy Compare"

- Select the measurement data of the smaller (420) chart

- Load the ICC Profile from point 1 as reference.

- Note the resulting color differences from the above

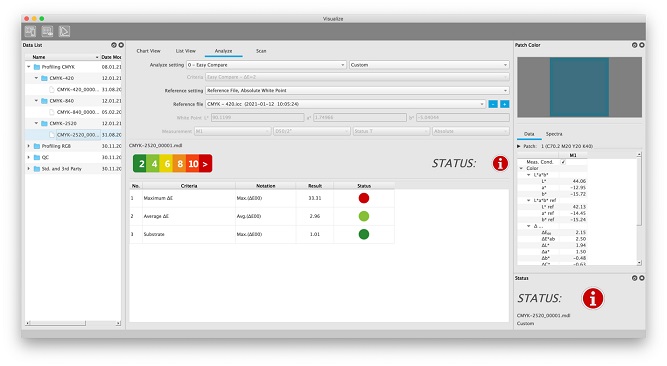

- Select the measurement of the larger chart

- Load the ICC Profile from point 1 as reference

- Check the resulting colour differences and compare them to the previous

Conclusion: If the colour differences are much larger at the last step compared to previous it looks like your ICC profile may not be the best at capturing and describing the print process in question here. Use a chart with more patches and go again, running the same check.

It is important to note that the print process could be unstable and not uniform (there are other checks that be performed to analyse uniformity) - this can also result in a wide difference between your checks above.

To find out more about the above - myiro products & colour management please contact us at info@colourgraphicservices.com