Densitometer and Spectrophotometer - What is the Difference?

These are the two colour measurement instruments we get asked the most about. Each has their place, and purpose, so in order to decide which is appropriate it is essential that we delve into each devices characteristics, details and functionality.

1. Densitometers

Densitometers traditionally come up with a density 'figure' when measuring a solid patch of colour, usually Cyan or Magenta or Yellow or Black (print process colours). Printers will recognize densities like 1.45 for Cyan and Magenta, 1.05 for Yellow and 1.7 for Black, based on ISO or ANSI Status T.

A densitometer uses a filter that is complimentary to the colour being measured.

- Cyan -> Red filter

- Magenta -> Green filter

- Yellow -> Blue filter

As such we can describe a densitometer as a colour blind instrument. Simply put the filter makes the colour appear a shade of black and density is based on a logarithmic calculation. i.e Density = Log10 (remission). Remission is a measurement of reflected light, which means 1.0 is perfectly reflective and 0.0 is perfectly absorbent.

Using the equation above, a grey patch that has a remission of 0.50 (or 50% reflection), would yield a density of 0.30 D. This makes a densitometer great for determining ink film thickness (density) and when used correctly will easily pick up large, and subtle,variations in density that the human eye cannot detect.

A densitometer easily becomes the printers friend as they can also provide additional measurement data for;

- Dot Area

- Ink Trapping

- Dot Gain

- Print Contrast

- Slur and Doubling

It is important to understand that a densitometer does NOT measure the actual half tone dots - it measures the density or tone value. Mathematics is then used for dot area and dot gain calculations.

Monitoring tone reproduction quality is especially important across all print processes, offset, flexo and digital. Just getting the solid densities in tolerance does not guarantee good quality colour reproduction. Some densitometers are capable of measuring according to one status type.

Therefore it is important to know what density status you are using and to always identify that when communicating or reporting density measurement values.

As a Guide;

- Status T, with no polarisation filter is commonly used in the USA

- Status E, with polarisation filter is used throughout Europe

- Status A, M and I maybe used in other applications like photographic

There is no right or wrong here other than to choose a set, stick to it and communicate it effectively.

Densitometers are very effective in the press room for process and quality control.

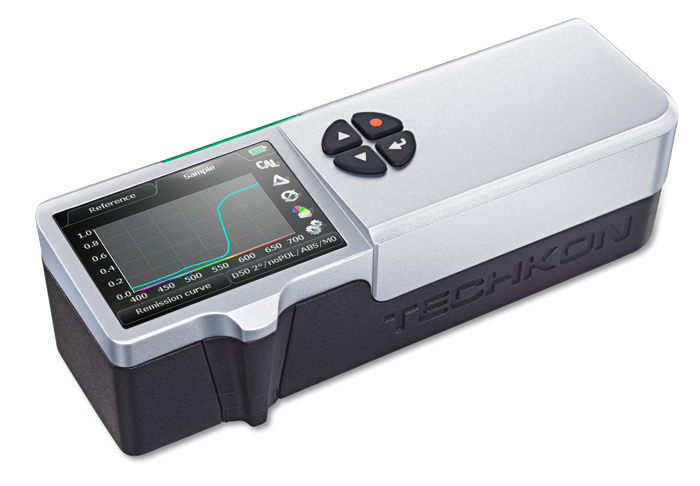

2. Spectrophotometers

A spectrophotometer is a complex precision instrument and therefore will always cost more than a densitometer. A Spectrophotometer typically captures a colour sample from across the visible spectrum (400 ~ 700 nano-meters) and provides a spectral data curve or spectral 'fingerprint'. With spectral data you are able to qualify paper and ink.

- Is the ink supplied within the required tolerance

- i.e. A colour spectrophotometer can tell you if your CMYK ink set can print within ISO 12647-2 tolerances

- Or if the spot colour is within dE (delta E) tolerance to match the required brand colour

The spectral data is usually converted to metrics to describe the colour, such as L*C*h* (Lightness, Chroma and Hue) or L*a*b*. These metrics closely resemble how we perceive colour.

There are Different Types of Spectrophotometers Used in Industrial Applications Like;

- Automotive paints

- Architectural finishes and coatings

- Paint formulation and finishes

- Ink formulation and finishes

- Plastics

And, In Print Areas For;

- Paper and substrate manufacture

- Ink and colorant formulation

- Proofing calibration and verification

- Press room colour control and print QC/QA.

Spectrophotometers are Also Commonly Used for Colour Management;

- Image capture (think colour scanners and digital cameras)

- Displays (colour monitors)

- Inkjet, digital and wide format printers for CMYK or RGB output

- In fact anywhere in print where colour measurement and colour reporting is required

For more information about Colour Management training and the full TECHKON instrument range please contact us at info@colourgraphicservices.com