Situated in the sprawling westward industrial spread of Melbourne at Truganina, lies a printing company of distinction and achievement that few are fully aware of.

"We like to fly under the radar," says Lithocraft Group Development Manager Shane O'Neill, "we focus on delivering the best possible service to our customers and as far as possible keep a low profile."

With the firepower of three huge manroland presses, a 708, 706 and 505. plus extensive finishing and a close partnership with Asia's largest sheetfed printer C&C Printing Co Ltd., the radar is likely to beep now and then, particularly when Lithocraft's client list includes some of the biggest names in FMCG, Pharmaceuticals, Automotive, Energy and Finance.

"Our customers love the one-stop choice of local or offshore production," says O'Neill. "When large volumes with longer lead times are called for, they experience the same high levels of service, order tracking, automation, reporting, W2P and, most importantly, quality, particularly where colour is concerned."

The C&C nameplate sits proudly alongside Lithocraft's at the entrance to the facility, testimony to the long and close association that also delivers global reach covering North America, Europe and most of Asia.

Lithocraft was established by Iain Morley in 1963, with Kevin Pidgeon joining in 1969. Nick O'Sullivan, the current Managing Director, commenced with the company in 1993. The company motto is: "Passionate people, driven by excellence." The passion shows in the pleasant work atmosphere of the purpose-built facility and the attitude of all staff encountered - they live and breathe print. The excellence is all around with awards, print samples, logistics and choice of equipment. ISO 9001 Quality Assurance and 14001 Environmental certifications have been joined by ISO 12647-2 Mellow Colour Proficient Printer.

Colour Graphic Services was chosen to implement Lithocraft's ISO colour assurance program using the Mellow Colour tools from the UK; beginning with colour quality systems training in February 2015, followed by a Mellow Colour ISO12647-PP audit which was passed.

David Crowther of Colour Graphic Services says: "A minimum audit score of 70% for the Mellow Colour Quality Management System is required to be certified as a 'Proficient Printer' under ISO 12647 specifications. Typically, we will see incremental improvements over the next few six-monthly audits as the culture of total colour assurance embeds into an organisation. I am delighted to say that, within only one year, Lithocraft's audit score has moved rapidly upwards and is now 95% - an exceptional result in such a short time."

Crowther attributes this remarkable result to the time, patience and passion devoted by key staff involved in the process. "Prepress Manager Paul Salmon and Print Manager Stuart Clark worked tirelessly together to understand and communicate to staff the demands and benefits of ISO 12647 colour. Lithocraft is a showcase example of integrating the culture of ISO colour standards across all departments, with a shared determination to achieve the best results for customers."

Prepress Manager Paul Salmon, a former Show-Ads veteran with considerable experience in colour, comments: "It's just remarkable the way that the Mellow Colour ISO 12647 process has enabled us to pinpoint any colour issues and fix them with total confidence. We've come to the point where we can even identify any batch issues with inks, plates and paper stocks themselves, and alert the suppliers, which naturally requires a level of transparency, trust and understanding."

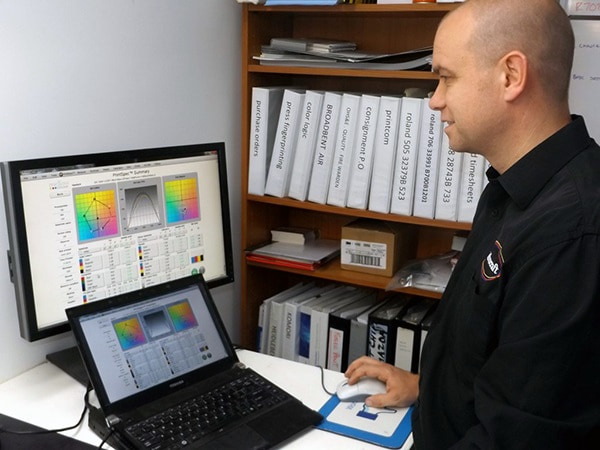

He adds: "Using the PrintSpec software provided by Colour Graphic Services, we are able to go beyond just specifications and actually see how a job is performing on press. The PrintSpec reporting is spot on - it measures CIE L*a*b* data so is evidence of actual colour performance."

Lithocraft plans to move to the ISO 12647-2:2013 revision as soon as practical and already has the M1 specified spectrophotometers needed to cope with OBCs (Optical Brightening Compounds) which are increasingly added to proofing papers and print stocks.

Any systemic barriers between prepress and press departments, if there were any, have melted away into a smooth continuum of colour workflow excellence. Print Manager Stuart Clark often accompanies sales personnel on client visits, something which colour-critical customers do not often see.

"Understanding real customers' needs enables us to be better printers," he says, adding: "We even go upstream to fashion photographers sometimes and work with them to deliver image files that are optimised for the job. If the photographer can understand the differences in reproducing colour on coated or uncoated stock; one hundred percent recycled versus say fifty percent; it goes a long way to helping these image creators think about the end printed result, and not only the RGB image they see on monitors."

Clark, originally a printer from Scotland who was introduced to Lithocraft by manroland following his marriage to an Australian, adds: "We now find it absolutely easier to hit the right PMS and spot colours using just process colours since PrintSpec is working with the L*a*b* data."

The training and culture change work undertaken by David Crowther involves adjustments to Rips, proofing, file preparation and measurement, culminating in data analysis using PrintSpec, archiving of historic data and regular reporting; drilled down to specific jobs if necessary.

Shane O'Neill is particularly impressed in the results, which have enabled his sales team to win new business. One leading men's fashion label was finding their printed advertising and catalogue reproduction was lacking detail, particularly in the shadows, and some colours were not matching fabrics closely enough.

"The PrintSpec process helped us win this account," says a delighted O'Neill: "We were able to deliver brand integrity and consistency for the client, and show fabric shadow detail where before it was just a dark mass."

He adds: "It is very important to talk customers through the ISO 12647 process and convey the benefits it can consistently achieve. Likewise, with our offshore partner C&C Printing, we can now communicate colour data that enables them to hit the same targets that we hit here. Most of our clients have been with us long-term and others by referral, so we must be doing something right!"

Lithocraft already has W2P online portals for its customers and will install digital printing capability for short runs in April 2016. "All things digital will get stronger," says O'Neill, "but the same principles of measurement and control over colour will still apply. In this, Mellow Colour ISO 12647 will be just as important to us as it has become in our litho offset production."

Crowther concludes: "It's a real pleasure to visit and ISO audit a company such as Lithocraft because the passion and commitment they show to colour is aligned with my own, and that of Mellow Colour!"